How to Choose the Right Industrial Automation Software for Your Business

In today's fast-paced manufacturing landscape, choosing the right industrial automation software is crucial. According to a recent report by McKinsey, companies that embrace automation can boost productivity by 30% or more. However, the decision-making process is complex. Many businesses struggle to identify software that aligns with their specific needs.

Numerous options exist, but not all are created equal. Some software packages fail to integrate seamlessly with existing systems, leading to costly downtimes. As highlighted in a study by Deloitte, 47% of firms reported implementation challenges. This highlights the importance of not only functionality but also compatibility when selecting industrial automation software.

Investing time to evaluate different solutions can lead to significant long-term benefits. Businesses must consider scalability, user-friendliness, and ongoing support. Neglecting these factors could result in subpar performance and lost opportunities. A thoughtful approach in choosing software can ultimately shape a company's operational efficiency and success.

Understanding the Basics of Industrial Automation Software

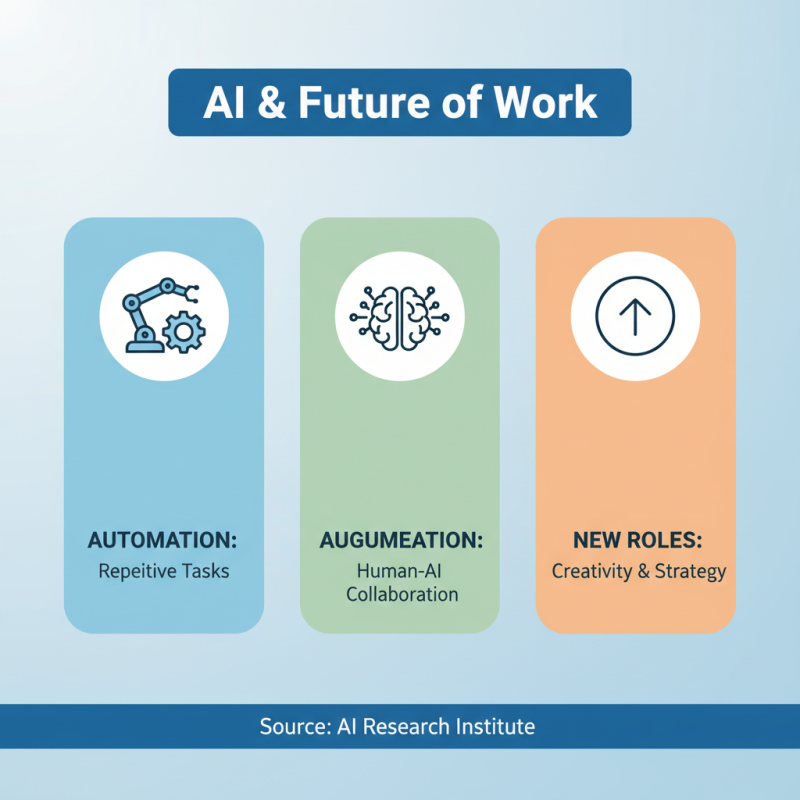

Industrial automation software plays a crucial role in modern manufacturing. It streamlines processes, reduces errors, and enhances productivity. According to a report from the International Federation of Robotics, industrial automation adoption is expected to grow by 10% annually. This surge indicates a clear trend towards digital transformation in industries.

Understanding the basics of industrial automation software is essential. Many solutions integrate various operational aspects, like inventory management and production scheduling. However, these systems can be complex. For instance, a study by McKinsey found that up to 70% of automation initiatives fail to meet their goals. Identifying the right features and functionality for your specific business needs is critical. Customized solutions often yield better outcomes than generic ones.

Data integration is another key aspect. Automation software needs to communicate with existing systems. A report from Market Research Future suggests that poor integration can lead to inefficiencies. Many businesses experience disruptions during this process. Evaluating your current systems is essential before making a transition. Addressing these challenges early can enhance the chances of successful implementation.

Identifying Your Business Needs and Objectives

When selecting industrial automation software, understanding your business needs is critical. According to a report by the International Society of Automation, about 70% of companies fail to identify specific goals before implementing new technology. This oversight can lead to wasted resources and unmet expectations.

To avoid pitfalls, start by analyzing current processes. Look for areas that require improvement. Is it production speed, accuracy, or inventory management? Data from a recent McKinsey study highlights that companies that align technology to their core objectives can see productivity gains of 20-30%.

Engage with team members at all levels. Their insights can reveal practical demands that might not be evident in reports. Often, there's a gap between executive visions and the realities on the floor. Addressing these discrepancies can refine your software choice. A more tailored solution increases the likelihood of a successful implementation and return on investment.

Evaluating Key Features and Capabilities of Software Options

Choosing the right industrial automation software is crucial for optimizing production processes. A recent industry report noted that 67% of manufacturers reported improved efficiency after adopting automation solutions. Yet, with numerous software options available, evaluating their key features is essential.

Focus on scalability. As your business grows, your software should adapt. Many systems lack this flexibility, creating future challenges. Integration capabilities also matter. Ideally, your software should connect seamlessly with existing equipment and technologies. Overlooked integration can lead to data silos, affecting decision-making.

**Tip:** Create a list of must-have features. Prioritize functionalities like real-time monitoring, reporting, and user-friendly interfaces.

Data security cannot be ignored. As automation increases, so do cyber threats. Ensure your software has robust security measures in place. This often requires thoughtful consideration, as some systems may focus more on functionalities rather than security.

**Tip:** Engage with IT specialists early in the selection process for informed decisions.

How to Choose the Right Industrial Automation Software for Your Business

| Feature | Importance Level | Description | Example Use Cases |

|---|---|---|---|

| User Interface | High | Intuitive and easy-to-navigate interface for all user levels. | Training new employees or quick troubleshooting. |

| Integration Capability | High | Ability to integrate with existing systems and equipment. | Connecting legacy systems with new automation solutions. |

| Scalability | Medium | Capacity to grow with the business needs. | Expanding production lines without major software overhaul. |

| Support & Maintenance | High | Availability of support services and documentation. | Ensuring minimal downtime during software issues. |

| Data Analytics | High | Tools for analyzing production data and performance metrics. | Identifying inefficiencies and optimizing production processes. |

| Cost | Medium | Total cost of ownership including subscription, maintenance, and upgrades. | Budgeting for software implementation and ongoing costs. |

| Customization | Medium | Flexibility to customize the software to meet specific needs. | Tailoring workflows to match unique production requirements. |

Comparing Costs and Return on Investment

When selecting industrial automation software, understanding its cost versus return on investment is essential. Many businesses overlook the total cost of ownership. Initial purchase prices can be misleading. Hidden costs, such as maintenance, training, and updates, often emerge later. It's vital to factor these into your calculations.

Evaluating ROI involves more than just numbers on a spreadsheet. Consider how the software will affect productivity. For instance, does it reduce downtime? Can it streamline operations? If the software saves an hour of labor each day, how does that translate to annual savings? Sometimes, the most expensive options provide the best long-term gains.

Also, reflect on potential drawbacks. Implementation can be disruptive. Staff may resist new systems. Will they require extensive training? This could lead to temporary productivity dips. Balancing these factors is crucial. The right software can transform operations, but the choices made must align with your unique business needs.

Reviewing Vendor Reputation and Customer Support Services

Choosing the right industrial automation software goes beyond features. Vendor reputation holds significant weight. A recent industry report found that 70% of customers value strong vendor support. This influences their software choice greatly. Businesses often face frustration when support is lacking. Poor response times can lead to costly downtimes.

Customer support services should be a priority. Data shows that 60% of users rely on forums and community help when official support falls short. Not all vendors provide adequate training. Many companies underestimate the importance of onboarding. This can hinder effective software implementation, leading to wasted time and resources.

Research reveals that automation tools with high customer satisfaction rates offer better long-term results. Yet, the reality is that some vendors fail to maintain positive customer relationships. Negative reviews can serve as red flags. Understanding these factors empowers businesses to make informed decisions.

Related Posts

-

Top 10 Industrial Automation Software Solutions for Streamlining Production

-

How to Choose the Right Industrial Automation Software for Your Business

-

Understanding Control Systems Automation for Enhanced Efficiency and Performance

-

Top Automation Control Trends to Watch in 2025 for Enhanced Efficiency

-

How to Choose the Best Process Automation System for Your Business in 2025

-

How to Build and Optimize Automatic Systems for Maximum Efficiency